- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

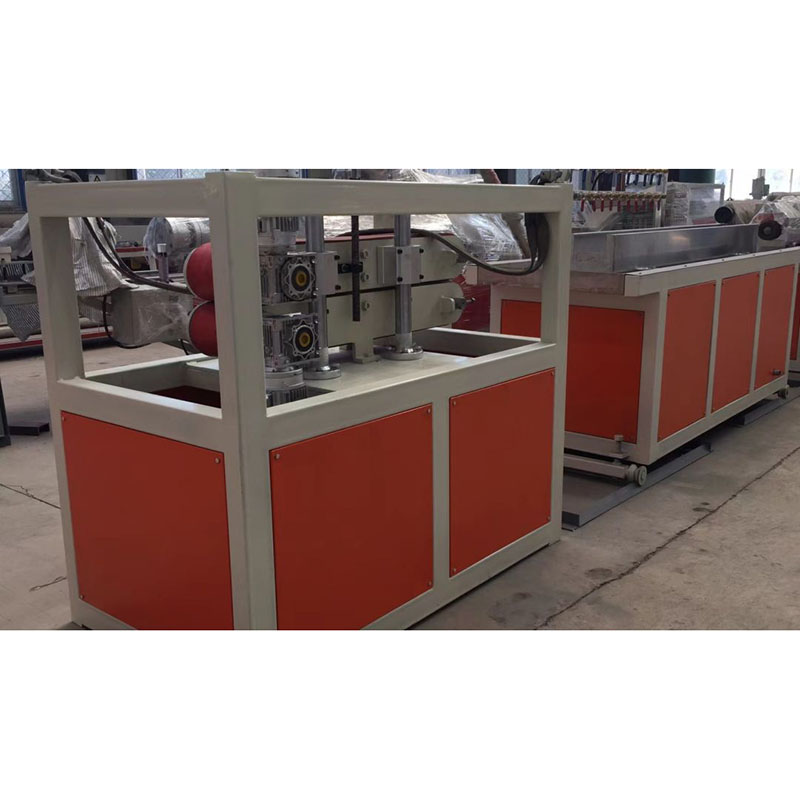

PVC Sealing Strip Equipment

PVC sealing strip equipment has been used in the production of automobiles, doors and windows, cabinets, refrigerators, containers and other industries. According to the requirements of different industries, we have developed automobile sealing strips, mechanical sealing strips, door and window sealing strips and other products.

Send Inquiry

PVC sealing strip equipment has been used in the production of automobiles, doors and windows, cabinets, refrigerators, containers and other industries. According to the requirements of different industries, we have developed automobile sealing strips, mechanical sealing strips, door and window sealing strips and other products.

Features

●High output and low energy consumption.

●Screw geometric parameters and reasonable design can produce different products for different raw materials. The screws have different length-to-diameter ratios and structures to meet the needs of different customers.

●The barrel heating section has two structures, grooved and smooth, to meet the needs of different raw materials.

●The screw and barrel are made of high-performance alloy steel, which has the advantages of wear resistance, corrosion resistance, and high strength.

●The whole machine has compact and reasonable design, convenient operation and simple maintenance.

|

Raw materials |

PVC granules. |

|

Process |

Feeding Extrusion Shaping Traction Rewinding Product testing application |

|

Production |

40-50kg/h Reasonable floating according to material characteristics and product specifications |

|

Machine color |

Light gray & dark white Guard plate uses orange or sky blue |

|

Factory requirements |

Foundation, construction, earthwork and wall engineering construction; |

|

Power supply voltage |

Supply of cranes, forklifts and other lifting equipment; installation materials and tools; |

|

Wires/pipes/cables/compressed air |

Space: (M*M*M): 14M (length) × 1.5M (width) × 2.5M (height); |

case

product display

|

1 |

specifications and models |

SJ-65 |

|

2 |

Screw diameter |

65mm |

|

3 |

Long diameter ratio of screw |

28:1 |

|

4 |

Screw structure form |

PVC Special screw rod |

|

5 |

Machine cylinder structure |

One machine tube |

|

6 |

Screw rod, machine barrel material |

38CrMOALA |

|

7 |

Screw, barrel nitride treatment |

nitrogen treatment |

|

8 |

Screw rod, barrel service life |

About 1-2 years |

|

9 |

Power of the main drive frequency conversion motor |

15KW Siemens Bead Motor |

|

10 |

reduction box |

Jiangyin or Changzhou produced plastic machinery special speed reducer |

|

11 |

Bottle heating power |

12KW |

|

12 |

The cooling mode of the cylinder |

forced air cooling |

|

13 |

Cooling fan power |

4×0.18KW=0.72KW |

|

14 |

Feed method |

Self-weight feeding |

|

15 |

Speed control system of main drive variable frequency control motor |

15KW frequency conversion controller (ABB frequency converter) |

|

16 |

Host electrical appliances |

Siemens low-voltage electrical appliances, Omron digital explicit intelligent temperature controller, ABB frequency converter, human working station structure electric control cabinet. |

|

17 |

Host external power supply |

Three-phase five-line system Total installed capacity of 34KW | + 4KW |

|

18 |

Host loading system |

Stainless steel hopper |

|

Item times |

project |

Requirements specification |

|

mould |

6-18mm, prepared according to the samples or drawings |

|

|

1 |

structural style |

Building block superposition machine head |

|

2 |

Mold-head and die-core material |

45 # quality treatment |

|

3 |

Production of different specifications and models of products |

Replace extrusion molds of different sizes and supporting setting devices |

|

4 |

Heating mode of mold |

Use heating non-changing heating sheet heater |

|

5 |

Mold service life |

About 3-5 years |

|

Item times |

project |

Requirements specification |

|

1 |

Length of diameter sink |

2.4M |

|

2 |

Water plate material |

stainless steel |

|

3 |

Longitudinal mobile motor power |

0.55kw |

|

4 |

Structural type |

Spray water for cooling, the pump power is 0.75KW |

|

5 |

Finalize the way |

Water-cooled molding mold |

|

6 |

Reservoir box body, pipeline material |

stainless steel |

|

7 |

Front and rear moving range |

800 mm |

|

8 |

Adjust the range left and right |

50 mm |

|

9 |

Up and down range |

80 mm |

|

Item times |

project |

Requirements specification |

|

1 |

mode of traction |

To roll type |

|

2 |

Pull effective width |

120 |

|

3 |

pulling motor |

0.75KW |

|

4 |

hauling speed |

And 1-12 m / min |

|

5 |

Speed control |

Frequency conversion control |

|

6 |

Tape material |

Wear-resistant silicone |

|

7 |

The clamping way |

hand movement |

|

Item times |

project |

Requirements specification |

|

1 |

Volume collection method |

The moment type |

|

2 |

The meter |

encoder |

|

3 |

Pressure tight way |

pneumatic |

|

4 |

Receive the diameter of the coil |

Inner 80, outer 600mm |

|

5 |

Discharge method |

Manual manual |