- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

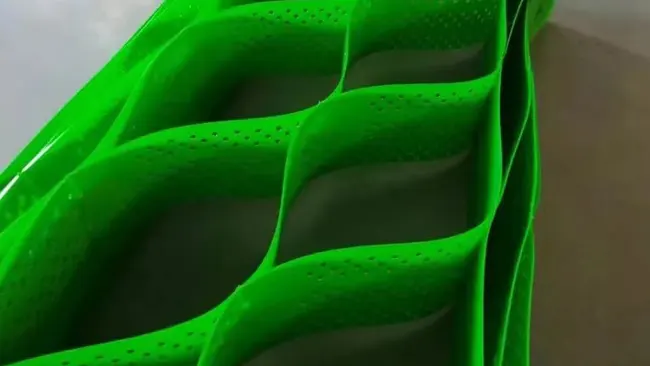

China Welding Distance 400mm Geocell Production Line Manufacturers, Suppliers, Factory

China Welding Distance 400mm Geocell Production Line is one kind of products from Eaststar factory. As the one of leading manufacturers and suppliers in China, we provide price list if you want. Our factory offers high quality Welding Distance 400mm Geocell Production Line. You can customize our products according to your ideas.We sincerely look forward to becoming your reliable long-term business partner!

Hot Products

PA POM Sheet Extruder Machine

The PA POM Sheet Extruder Machine of: single-screw extruder, three-roller calender, cooling bracket with automatic trimming device, rubber roller traction machine, and winding machine. Products of different specifications can be produced according to different requirements of customers. Sheets with different surfaces can be produced with smooth, orange peel, and matte surfaces.Car Floor Mats Overlock Sewing Machine

Eaststar, a renowned factory, specializes in producing Car Floor Mats Overlock Sewing Machines. What sets Eaststar apart is their commitment to providing high-quality machinery at a competitive price point. Our dedication to affordability and quality makes them a trusted choice for manufacturers in the automotive industry.Disposable Seedling Cup Plug Equipment

Disposable Seedling Cup Plug Equipment technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm. Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mmPET Root Plant Root Protection Equipment

root controldevice is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. PET Root Plant Root Protection Equipment is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reducer motor 0.55KW and 1:10 special reducer, to ensure the stability of feeding speed! 4: Ceramic heating block: new ceramic heating block, heating fast and low power consumption, the temperature can be adjusted freely, according to the thickness of different materials. 5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: Delta PLC control, 6: The machine adopts hydraulic balanced distribution design, the overall balance is better, to solve the situation of the high and low in the production to prolong the use time of the mold.PS Blister Packaging Sheet Production Line

Eaststar is a trusted manufacturer from China that specializes in the production of PS blister packaging sheet production lines. With years of experience in the industry, Dongfang Star has gained a reputation for delivering high-quality and reliable production lines for producing superior PS blister packaging sheets. Their products are widely used in the packaging industry and are known for their efficiency, durability, and cost-effectiveness. If you're in need of a dependable and efficient PS blister packaging sheet production line, Dongfang Star is an excellent choice.PLA Degradable Plastic Sheet Production Line

If you're in search of a PLA Degradable Plastic Sheet Production Line, our esteemed factory has you covered. What's more, for a limited time, we're offering exclusive discounts on this state-of-the-art machinery. Don't miss out on this opportunity to enhance your production capabilities while enjoying significant cost savings.