- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

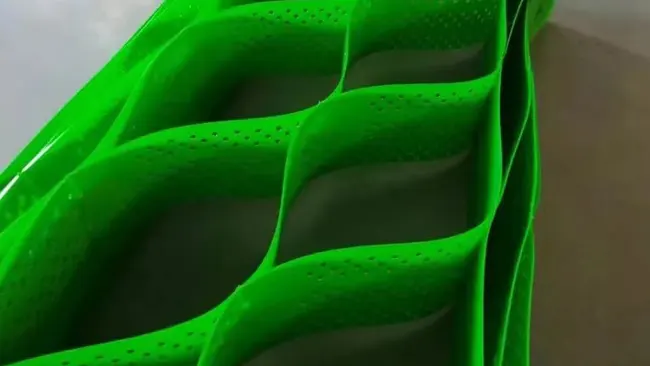

Geocell Grid Extrusion Machine

Eaststar, a reputable supplier in the industry, specializes in providing top-of-the-line Geocell Grid Extrusion Machines. These advanced machines are designed for the precise manufacturing of geocell grids, essential for various civil engineering and construction applications. Any inquiries and problems please feel free to send emails to us and we will reply you soon.

Send Inquiry

With Eaststar as your supplier, you can expect cutting-edge machinery equipped with state-of-the-art features and components, ensuring efficient and accurate production of high-quality geocell grids. Trust in Eaststar's expertise and commitment to delivering reliable and top-notch extrusion equipment for your geocell grid production needs.

Feature:

1. It offers flexible expansion, making it collapsible for transport and easily deployable into a mesh-like structure during construction. It can be filled with loose materials like soil, gravel, or concrete, forming a robust structure with strong lateral confinement and high rigidity.

2. The material is lightweight, wear-resistant, chemically stable, and resistant to photodegradation, acid, and alkali. It is suitable for various soil conditions, including deserts.

3. It provides excellent lateral confinement and anti-slip properties, preventing deformation and effectively enhancing the bearing capacity and load dispersion of the subgrade.

4. The ability to adjust geometric dimensions such as the height and welding distance of the geocell grid meets diverse engineering requirements.

5. It allows for easy expansion and contraction, resulting in a compact transport size and facilitating quick assembly. In essence, when a load is applied to the subgrade, an active zone is formed beneath the load, which then exerts pressure on the transitional zone, causing an uplift in the passive zone. This means that the bearing capacity of the foundation is determined by the shearing force along the slip line and the forces acting on the active, transitional, and passive zones. The process is clearly observable not only on sandy bases but also on soft subgrade roads, albeit at a slower rate of formation. Even with good subgrade materials, lateral movement cannot be completely avoided. Typically, highway subgrades are several meters above the ground, making it less prone to water absorption and erosion. However, long-term settlement still exists. The reasons behind this phenomenon include rainwater infiltration, material loss, and base sinking. Additionally, under the prolonged action of wheel loads and vibration forces, the material undergoes lateral displacement towards both sides of the cross-section, which is undeniably another significant factor. Taking highways at all levels in our province as an example, there is a noticeable "S"-shaped groove on the main driving lanes, where the road surface has been pressed down. Some highways are no exception, with the sensation of stronger vibrations when driving on the main lanes compared to the overtaking lanes. This phenomenon is particularly evident in the bridge connection section (commonly known as "bridgehead jumping"). This type of settlement in the form of a grooved subgrade is a typical result of lateral movement of subgrade materials.

Geocell Grid Extrusion Machine