- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Geogrid Equipment extruder machine Manufacturers, Suppliers, Factory

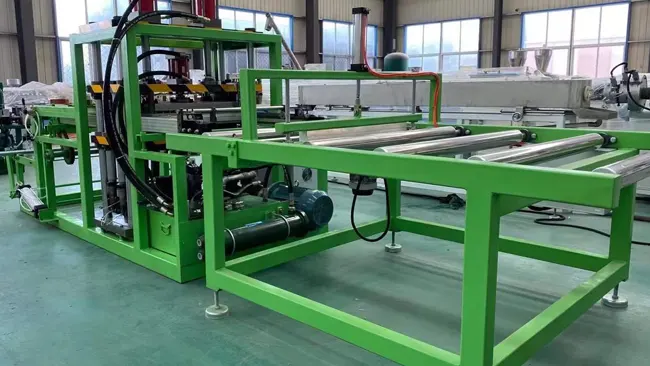

China Geogrid Equipment extruder machine is one kind of products from Eaststar factory. As the one of leading manufacturers and suppliers in China, we provide price list if you want. Our factory offers high quality Geogrid Equipment extruder machine. You can customize our products according to your ideas.We sincerely look forward to becoming your reliable long-term business partner!

Hot Products

Geocell Grid Extrusion Machine

Eaststar, a reputable supplier in the industry, specializes in providing top-of-the-line Geocell Grid Extrusion Machines. These advanced machines are designed for the precise manufacturing of geocell grids, essential for various civil engineering and construction applications. Any inquiries and problems please feel free to send emails to us and we will reply you soon.ABS Sheet Production Line

Eaststar is a renowned supplier specializing in the production of ABS sheet production lines. With cutting-edge technology and a commitment to excellence, Eaststar has established itself as a leading force in the industry. Their state-of-the-art production lines are meticulously designed to ensure high-quality ABS sheet manufacturing, meeting the diverse needs of industries worldwide. Through continuous innovation and a dedication to customer satisfaction, Eaststar sets a gold standard in the production line market, making them the go-to choice for businesses seeking top-tier ABS sheet manufacturing solutions.PS Blister Packaging Sheet Production Line

Eaststar is a trusted manufacturer from China that specializes in the production of PS blister packaging sheet production lines. With years of experience in the industry, Dongfang Star has gained a reputation for delivering high-quality and reliable production lines for producing superior PS blister packaging sheets. Their products are widely used in the packaging industry and are known for their efficiency, durability, and cost-effectiveness. If you're in need of a dependable and efficient PS blister packaging sheet production line, Dongfang Star is an excellent choice.Pvc Anti-slip Mat Equipment Soft Sheet Machine

Pvc Anti-slip Mat Equipment Soft Sheet Machine: The equipment mainly consists of a single-screw extruder, a three-roller calender, a 6-meter cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device.Rigid PVC Sheet Extruder Equipment

Qingdao Eaststar Plastic Machinery Co., Ltd. has always focused on sheet equipment, especially the research of Rigid PVC Sheet Extruder Equipment. The equipment can be customized according to the width and thickness of the product. The electrical parts of the equipment are all imported from abroad, which not only guarantees the quality of the equipment, but also guarantees the convenience of after-sales service. Our equipment is sold all over the world. Quality and service first is our company's business philosophy. Welcome friends from all over the world to come and purchase equipment。PET Root Plant Root Protection Equipment

root controldevice is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. PET Root Plant Root Protection Equipment is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reducer motor 0.55KW and 1:10 special reducer, to ensure the stability of feeding speed! 4: Ceramic heating block: new ceramic heating block, heating fast and low power consumption, the temperature can be adjusted freely, according to the thickness of different materials. 5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: Delta PLC control, 6: The machine adopts hydraulic balanced distribution design, the overall balance is better, to solve the situation of the high and low in the production to prolong the use time of the mold.