- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

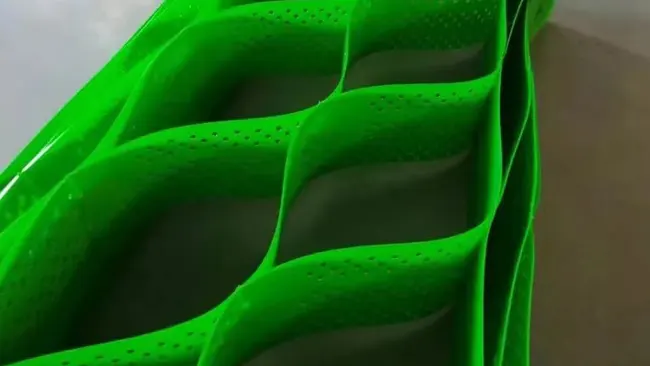

China Plastic Hdpe Geocell Erosion Extrusion Machine Manufacturers, Suppliers, Factory

Each individual member from our significant effectiveness gross sales workforce values customers' demands and small business communication for Plastic Hdpe Geocell Erosion Extrusion Machine,Plastic Gravel Stabilizer Geocell Extrusion Machine,Road Geocel Extrusion Machine,Parking Lot Geocell Extrusion Machine,Slope Stabilization Geocell Extrusion Machine, We hope we can have a friendly relationship with businessman from all over the world.

Plastic Hdpe Geocell Erosion Extrusion Machine, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

Hot Products

PC Plastic Sheet Extrusion Machine

Eaststar is a leading manufacturer and factory of PC plastic sheet extrusion machines. Our state-of-the-art machinery is designed with precision and efficiency in mind and has been trusted by our clients for years. As a dedicated manufacturer, we strive to provide our customers with the highest quality products and services. With our expertise and knowledge, we ensure that our PC plastic sheet extrusion machines meet the demanding needs of our clients. Choose Eaststar for all your plastic sheet extrusion needs and experience the difference that comes with working with a top-tier manufacturer.PP Sheet Printing Machine

Eaststar, a distinguished manufacturer in the industry, operates a cutting-edge factory dedicated to the production of PP Sheet Printing Machines. Renowned for their commitment to excellence, Eaststar designs and manufactures machinery that sets the standard for precision and quality in PP sheet printing.PLA Degradable Plastic Sheet Production Line

If you're in search of a PLA Degradable Plastic Sheet Production Line, our esteemed factory has you covered. What's more, for a limited time, we're offering exclusive discounts on this state-of-the-art machinery. Don't miss out on this opportunity to enhance your production capabilities while enjoying significant cost savings.PVC Edge Banding Equipment

PVC Edge Banding Equipment Technical parameters and configuration 1 Specification model SJ65-28/1 2 screw diameter 65mm 3 Screw length-to-diameter ratio 28:1 4 Screw structure type PVC special screw 5 Barrel structure Barrel integrated 6 screw, barrel material 38CrMOALA 7 Screw and barrel nitriding treatment Nitriding treatment 8 screw and barrel service life is about 3 years 9 Main drive variable frequency motor power 18.5KWNursery Tray Seeding Making Machine

Nursery Tray Seeding Making Machine technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm. Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mmSoft Pvc Sheet Extruder Machine Turtle Pattern Machine

The most important part of Soft Pvc Sheet Extruder Machine Turtle Pattern Machine is the three-roller forming machine, which has two smooth rollers and a tortoise shell roller in the middle.The processing procedures of the tortoise shell roller include: rough turning, dynamic balancing, fine turning, grinding, electroplating, engraving, frosting, and fine mirror grinding. The time for engraving the roller is relatively long, so the delivery cycle of the whole equipment is relatively long. Manufacturers who need to process and customize tortoise shell equipment must place orders in advance.