- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

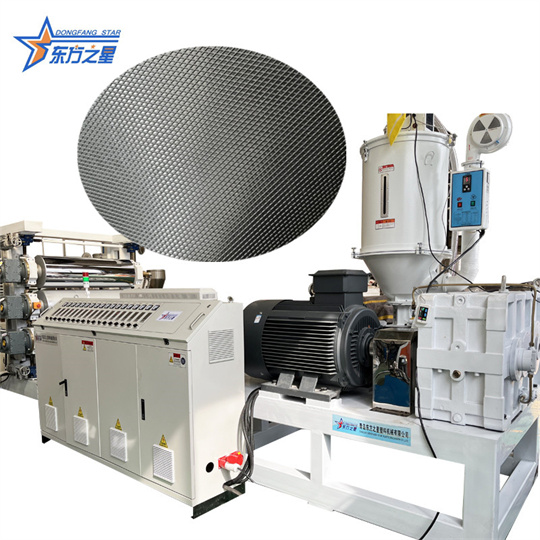

China Soft PVC Sheet Making Machine Manufacturers, Suppliers, Factory

China Soft PVC Sheet Making Machine is one kind of products from Eaststar factory. As the one of leading manufacturers and suppliers in China, we provide price list if you want. Our factory offers high quality Soft PVC Sheet Making Machine. You can customize our products according to your ideas.We sincerely look forward to becoming your reliable long-term business partner!

Hot Products

ABS/PC Co-extruded Lamp Tube Cover Equipment

Defects of The PP/PC lamp case production line : 1.ABS/PC Co-extruded Lamp Tube Cover Equipment suitable for the collision of rigid pipes and special-shaped materials; the specific configuration depends on different origins Product design plan! 2. The PP/PC lamp case production line Applicable raw materials: PC, PMMA, ABS, rigid PVC, PP, PE and other pellets 3. The PP/PC lamp case production line Applicable pipe diameter range: round pipes, semicircles, and special-shaped products within OD120mm. 4. The PP/PC lamp case production line Suitable for brazing and two-color through co-extrusion extruder and mold. 5. The PP/PC lamp case production line Different products can adopt water-cooling, cold-top, air-cooling and other processesHIPS Sheet Blister Machine

Eaststar, a distinguished supplier in the industry, specializes in providing top-of-the-line HIPS Sheet Blister Machines. These advanced machines are designed for precise manufacturing of blister packaging using High Impact Polystyrene (HIPS) sheets.Sincerely look forward to cooperating with you in the near future.PE Sheet Extrusion Line

Eaststar stands as a distinguished supplier and manufacturer of PE Sheet Extrusion Lines, renowned for their commitment to customization. With a focus on customization, they ensure that each extrusion line is optimized to meet the unique needs of their clientele, setting a standard of excellence in the field.PE Plastic Sheet Extrusion Machine

Eaststar, located in China, specializes in crafting customized PE Plastic Sheet Extrusion Machines. With a keen focus on precision and flexibility, these machines are designed to meet a wide range of specific requirements. Whether you need plastic sheets for packaging, construction, or any other application, Eaststar expertise ensures that their extrusion machines deliver top quality results. Trust in Eaststar to provide tailored solutions that exemplify the pinnacle of plastic sheet production technology.PVC Wall Panel Production Line

PVC wall panel production line consists of: ① Cone double main machine ② Glue extruder ③ Vacuum shaping table ④ Traction machine ⑤ Cutting machine ⑥ Material receiving rack The PVC wall panel production line adopts intelligent control, high degree of automation, stable operation, easy operation, and high production efficiency. In addition, our company has always adhered to the customer-oriented approach and always implemented the "turnkey" solution, providing customers with door-to-door installation, commissioning, production, and training and Raw material formula ensures that customers can produce independently and stably.Seedling Box Plug Tray equipment

Seedling Box Plug Tray equipment technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm. Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mm