- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

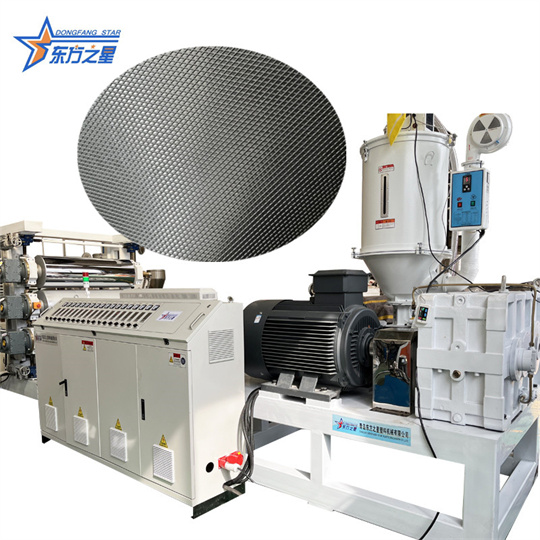

China soft pvc extruder sheet machine Manufacturers, Suppliers, Factory

China soft pvc extruder sheet machine is one kind of products from Eaststar factory. As the one of leading manufacturers and suppliers in China, we provide price list if you want. Our factory offers high quality soft pvc extruder sheet machine. You can customize our products according to your ideas.We sincerely look forward to becoming your reliable long-term business partner!

Hot Products

PS Blister Packaging Sheet Extrusion Machine

Eaststar, a reputable manufacturer based in China, offers cutting-edge PS blister packaging sheet extrusion machines that are designed to meet the needs of various industries. These machines have a specialized design that allows them to produce high-quality PS blister packaging sheets with precision and efficiency.PP Sheet Printing Machine

Eaststar, a distinguished manufacturer in the industry, operates a cutting-edge factory dedicated to the production of PP Sheet Printing Machines. Renowned for their commitment to excellence, Eaststar designs and manufactures machinery that sets the standard for precision and quality in PP sheet printing.Seedling Tray Seeder Making Machine

Based in China, Eaststar is a prominent supplier of Seedling Tray Seeder Making Machines. These machines are meticulously crafted to meet the demands of nurseries and agricultural enterprises. Eaststar's state-of-the-art factory employs cutting-edge technology to manufacture high-quality equipment. Collaborating with trusted suppliers, Eaststar ensures the use of top-notch components, ensuring the efficiency and durability of their machinery. With a reputation for advanced technology and reliable production capabilities, Eaststar is a preferred choice for suppliers worldwide in need of top-grade Seedling Tray Seeder Making Machines.PVC Edge Banding Equipment

PVC Edge Banding Equipment Technical parameters and configuration 1 Specification model SJ65-28/1 2 screw diameter 65mm 3 Screw length-to-diameter ratio 28:1 4 Screw structure type PVC special screw 5 Barrel structure Barrel integrated 6 screw, barrel material 38CrMOALA 7 Screw and barrel nitriding treatment Nitriding treatment 8 screw and barrel service life is about 3 years 9 Main drive variable frequency motor power 18.5KWPP/PC Lamp Case Production Line

Defects of The PP/PC lamp case production line : 1. The PP/PC lamp case production line suitable for the collision of rigid pipes and special-shaped materials; the specific configuration depends on different origins Product design plan! 2. The PP/PC lamp case production line Applicable raw materials: PC, PMMA, ABS, rigid PVC, PP, PE and other pellets 3. The PP/PC lamp case production line Applicable pipe diameter range: round pipes, semicircles, and special-shaped products within OD120mm. 4. The PP/PC lamp case production line Suitable for brazing and two-color through co-extrusion extruder and mold. 5. The PP/PC lamp case production line Different products can adopt water-cooling, cold-top, air-cooling and other processesPLA Degradable Plastic Sheet Production Line

If you're in search of a PLA Degradable Plastic Sheet Production Line, our esteemed factory has you covered. What's more, for a limited time, we're offering exclusive discounts on this state-of-the-art machinery. Don't miss out on this opportunity to enhance your production capabilities while enjoying significant cost savings.