- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Seedling Box making machine Manufacturers, Suppliers, Factory

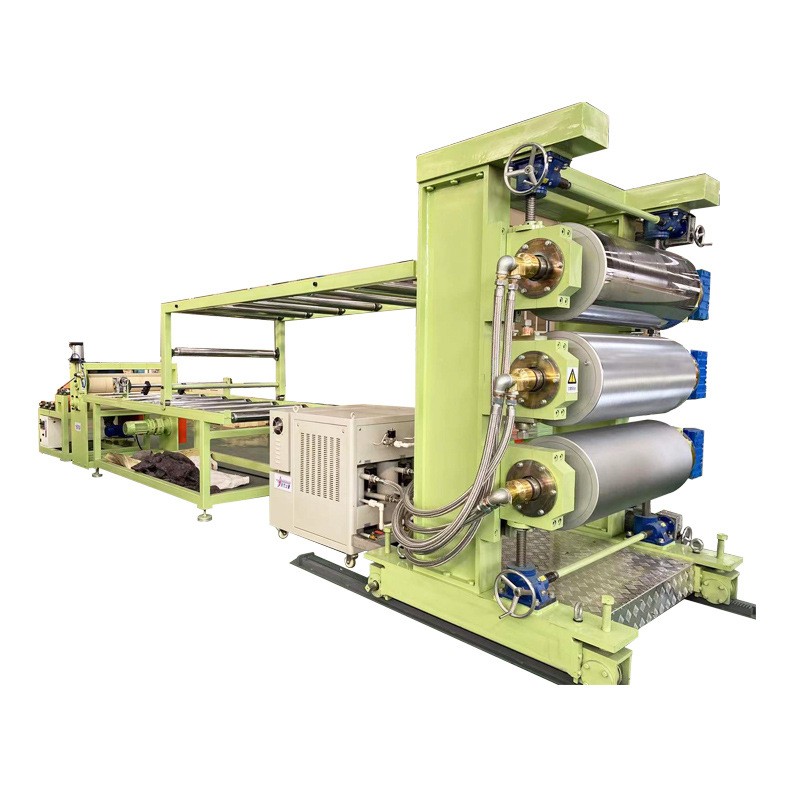

China Seedling Box making machine is one kind of products from Eaststar factory. As the one of leading manufacturers and suppliers in China, we provide price list if you want. Our factory offers high quality Seedling Box making machine. You can customize our products according to your ideas.We sincerely look forward to becoming your reliable long-term business partner!

Hot Products

PVC Transparent Soft Door Curtains Machine

PVC Transparent Soft Door Curtains Machine Qingdao EAST STAR Plastic Machinery Co., Ltd. is mainly engaged in plastic sheet equipment. Our company's PVC soft door curtain equipment mainly consists of five parts: super mirror roller part, motor drive system, gap adjustment system, electrical control system, and frame. composition. Our company's PVC soft door curtain equipment can produce PVC transparent soft door curtains with a width of 200-400 mm and a thickness of 0.5-5 mm. This PVC soft door curtain equipment can produce three types of soft door curtains, including glossy, matte and striped, in one machine. It not only achieves multiple uses in one machine and is easy to operate, but also helps customers greatly save costs.Seed Tray Vacuum Forming Machine

Seed Tray Vacuum Forming Machine technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm. Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mmPA Sheet Production Line

PA Sheet Production Line The production line consists of: single-screw extruder, three-roller calender, cooling bracket with automatic trimming device, rubber roller traction machine, and winding machine. Products of different specifications can be produced according to different requirements of customers. Sheets with different surfaces can be produced with smooth, orange peel, and matte surfaces.Car PVC Flooring Extrusion Machine

Eaststar, a reputable manufacturer in the industry, specializes in producing Car PVC Flooring Extrusion Machines. What sets Eaststar apart is their commitment to providing high-quality machinery at a competitive price point. The Car PVC Flooring Extrusion Machines manufactured by Eaststar are designed to meet the precise requirements of automotive PVC flooring production, ensuring efficiency and precision in every extrusion.Seedling Tray Making Machine

Eaststar, a distinguished manufacturer based in China, is at the forefront of producing high-quality Seedling Tray Making Machines. Their state-of-the-art factory and unwavering commitment to excellence have solidified Eaststar's position as a trusted supplier in the agricultural machinery industry.HDPP/PE plastic sheet geocell production line

HDPP/PE plastic sheet geocell production line is used to produce geocells. The first step of this product is to produce sheets, and then the sheets are cut online, and then the plastic sheets are connected through ultrasonic welding and other methods