- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Slope Stabilization Geocell Extrusion Machine Manufacturers, Suppliers, Factory

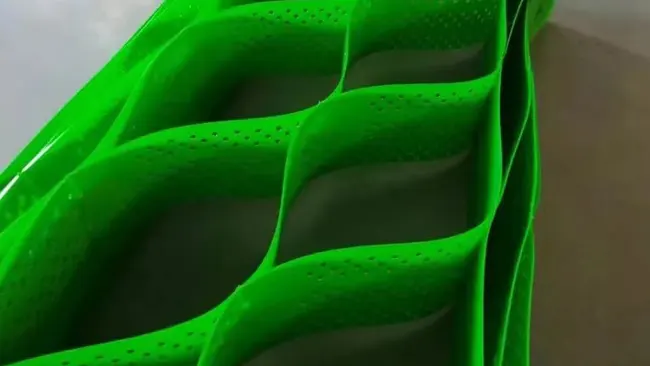

To continually enhance the management technique by virtue of your rule of "sincerely, great faith and high-quality are the base of company development", we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for Slope Stabilization Geocell Extrusion Machine,Plastic Gravel Stabilizer Geocell Extrusion Machine,Road Geocel Extrusion Machine,Parking Lot Geocell Extrusion Machine,Boden Geocell Kies Paddock Extrusion Machine, We sincerely welcome domestic and international retailers who calls, letters inquiring, or to vegetation to barter, we'll offer you you good quality merchandise along with the most enthusiastic services,We glance ahead towards your go to plus your cooperation.

Slope Stabilization Geocell Extrusion Machine Lamp, Due to the stability of our products, timely supply and our sincere service, we are able to sell our goods not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We'll do our best to serve your company, and establish a successful and friendly cooperation with you.

Hot Products

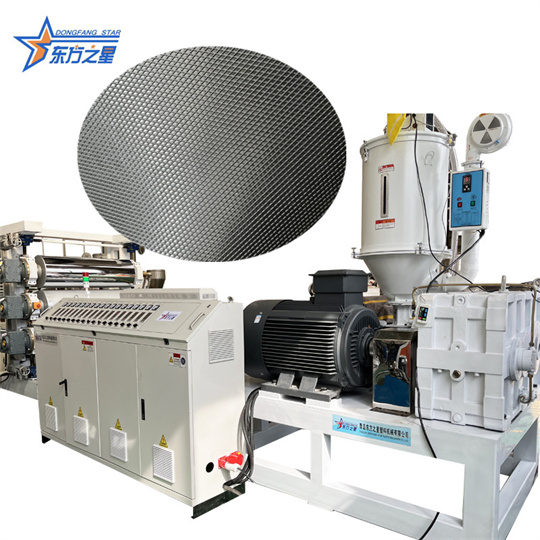

PP Sheet Extrusion Line

Eaststar stands out as a prominent supplier and manufacturer in the field of PP Sheet Extrusion Lines. Specializing in customization, they offer top-tier machinery tailored to specific production needs. With Eaststar expertise, you can expect precision and efficiency in the extrusion process, resulting in high-quality PP sheets. Whether for packaging, industrial applications, or any other purpose, their extrusion lines are crafted to deliver outstanding performance.Root Controller Making Machine

Eaststar, a renowned manufacturer based in China, specializes in crafting high-quality Root Controller Making Machines. Our state-of-the-art factory and commitment to excellence have positioned Eaststar as a trusted supplier in the agricultural machinery industry.PE Aluminum-Plastic Composite Panel Production Line

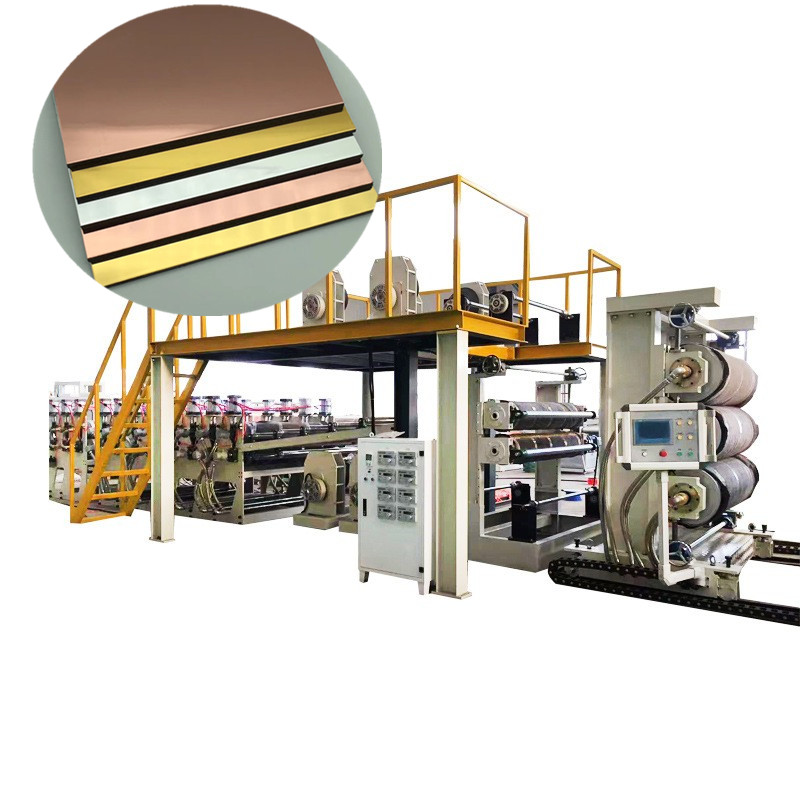

PE Aluminum-Plastic Composite Panel Production Line (also known as aluminum-plastic panel), as a new building material, and has been quickly favored by people for its economy, the diversity of optional colors, convenient construction methods, excellent processing performance, excellent fire resistance and noble quality. The unique properties of aluminum-plastic composite board determine its wide range of uses: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, purification and dust prevention projects. It belongs to a new type of building material. The products produced by the equipment are mainly suitable for the inner and outer wall PE composite board, the thickness of the product is from 1-6mm, the width of 1200-1500mm two models, the thickness of the aluminum foil is from 0.03-0.5mm, and the bonding process of polymer film or glue can be selected. The equipment has the advantages of one molding, stable extrusion, firm compound, good flatness and so on.PP PE Coated Pipe system machine

PP PE Coated Pipe system machine PP PE Coated Pipe system machine is mainly used for coating the surface of various metal pipes with a layer of plastic. Stainless steel pipe diameter: 1-200mm can be customized according to customer requirements; Surface coating materials for PP coated pipe equipment: PE, PP, PVC, PA, etc; Coating speed: 0.5-50 meters per minute. Production process of PP coated pipe equipment: Stainless steel pipes on the wire rack or material rack are first preheated by a heating device, then wrapped in plastic by the main machine coating mold, cooled by a circulating water tank, pulled by a traction machine to the wire storage rack, and then automatically cut to a fixed length. Due to different processing techniques for various profiles, the required equipment configuration and equipment are also different.High Quality Aluminum Plastic Panel Recycling Equipment

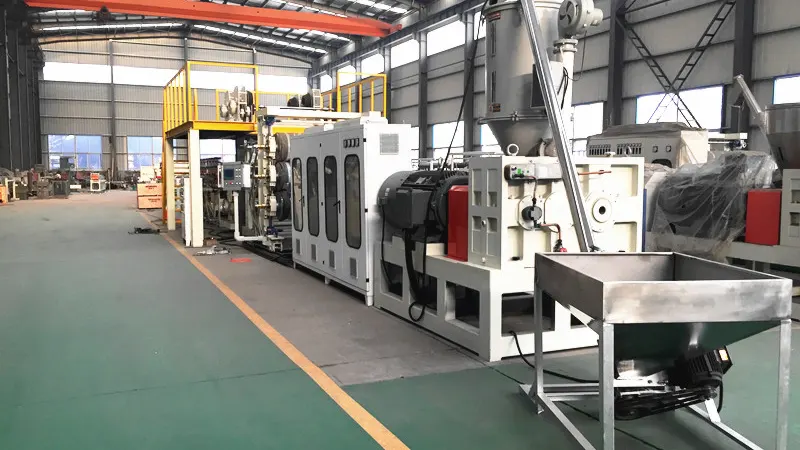

Qingdao East Star Plastic Machinery Co., Ltd. is mainly engaged in sheet material extruder equipment. High Quality Aluminum Plastic Panel Recycling Equipment is one of the important products produced by our company. We can match the equipment with corresponding output according to customer requirements. Friends from all over the world are welcome to purchase equipment.TPU/PE/PP/PS-300 Wide Sheet Extrusion Line

The TPU/PE/PP/PS-300 Wide Sheet Extrusion Line is designed for processing pellets or crushed mixtures of TPU, PE, PP, and PS. With a production capacity of **60-100 kg/h**, the line includes components from leading brands like Siemens and Omron. It features a 0.8-3mm sheet die, three-roll calender, and winding machine, ensuring high-quality output. The equipment meets stringent quality standards and includes comprehensive technical documentation for ease of operation and maintenance.