- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Root Controller Making Machine

Eaststar, a renowned manufacturer based in China, specializes in crafting high-quality Root Controller Making Machines. Our state-of-the-art factory and commitment to excellence have positioned Eaststar as a trusted supplier in the agricultural machinery industry.

Send Inquiry

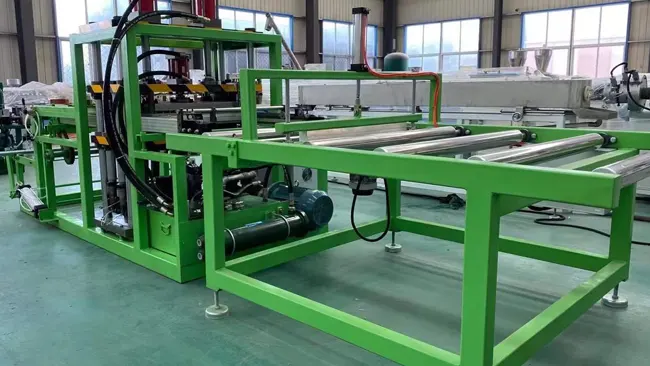

KG- 1000 series fully automatic root control container making machine

Root Controller Making Machine Introduction:

1. The equipment is mainly designed and made in accordance with the working principle of thermal pressure equipment, the process is: sheet —— feeding —— pressing —— pressure protection —— forming —— cutting etc, machine appearance clean and practical , plate processing all adopt center processing, to ensure the precision of all hole size, column and small appearance are hard chrome quenching treatment, ensure sliding and wear resistance, machine system editing adopt manual and automatic two methods, all actions can be a single operation.

2: The feed motor is driven by a servo motor with a power of 2 kW.

3: Feed discharging reducer motor 0.37KW shall cooperate with 1:10 special reducer to ensure the stability of discharging speed!

4: Ceramic heating block: the new ceramic heating block, heating up fast and low power consumption, the temperature can be freely adjusted according to the thickness of different materials.

5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: PLC control,

6: The machine adopts the hydraulic equilibrium distribution design, and the overall balance is better, and extends the use time of the mold.

Introduction of the equipment subject:

|

1 |

Forming (cutting) maximum length range |

0.5 m-infinite length (wholemold multiple cut) |

|

2 |

Forming (cut) width range |

1000mm, width canadjustable |

|

3 |

Suitable for sheet thickness |

0.40-0.90mm |

|

4 |

Maximum height of forming |

50mm |

|

5 |

production efficiency |

Equipment timing is 3-8 seconds / mode, specific according to the forming effect |

|

6 |

Product model and mold form |

Equipment is applicable to various waveform molds |

|

7 |

Demoldingmethod |

Two-way separation of mold |

|

8 |

Heatingmethod |

Each section is separately temperature-controlled and heated on a singleside |

|

9 |

Total heating power |

22 kW |

|

10 |

Temperature controladjustsystem |

Use a solid-state heating temperature controller to ensure a constant temperature |

|

11 |

Main motor power |

7.5KW |

|

12 |

Cooling system form and power |

The aluminum alloy beam is equipped with a water trough to ensure the cooling effect of the beam |

|

13 |

Rated maximum power of the whole machine |

32KW |

|

14 |

Actual energy consumption for normal production |

22KW |

|

15 |

Power supply, voltage |

380V 50HZ (three-phase and four-wire) |

|

16 |

Power of air pressure system |

0.4-0.8MPA |

|

17 |

Overall size of the whole machine |

5M long, 1.5M wide and 1.8 m high Length5000mm*width1500mm*Height1800mm |

|

18 |

Total weight of the whole machine |

3000KGaround |

Control root application

Control root container is a new rapid seedling raising technique to regulate root growth and has a unique effect in preventing root rot and unwinding of the main root.The control root container makes the side root shape thick and short.Will not form winding root, overcome the defects of conventional container seedling brings root winding, total root increased 30-50 times, high survival rate of seedlings, seedling cycle by half, transplanting management workload reduced, the container in addition to make the seedlings root strong, strong growth, especially for large seedlings planting and season transplanting and afforestation under bad conditions, has obvious advantages.

1, Root effect: control root seedling container has a special film, and the container side wall convex concave, the external protruding top stomata, when the seedling root growth outward downward contact with air (small hole on the side wall) or any inner wall, root tip stop growth, then germination of three new root continue to grow outward, when contact with air (small hole in the side wall) or any part of the inner wall, stop growth and after the root head three new roots.The number of roots thus increases with a series of 3, greatly increasing the number of short and thick side roots, and the total number of roots increasing by 20-30 times compared with conventional field seedlings.

2. Root control effect: in general seedling raising technology, the main root is too long, and the lateral root development is weak.Using the conventional container seedling raising method, the winding phenomenon of seedling roots is very common.Control root technology can make the side root have a short and thick shape and a large number of development, while limiting the growth of the main root without forming wound roots.

3. Promote growth process: due to the dual role of the root control container and the substrate used, the root system of seedlings is strong and robust, which can store a large number of nutrients, meet the growth needs of seedlings in the initial stage of colonization, and create good conditions for the survival and rapid growth of seedlings.Transplanting does not hurt roots, not subject to seasonal restrictions, simple management, high survival rate, and fast growth rate.

Root control container advantages:

● The nursery cycle is shortened by about 50%

● Post-stage management workload reduced by 50%-70%

● The total number of lateral roots of plants is 20-30 times higher than that of conventional seedlings.

● It completely solves the problem that large seedlings are difficult to transplant in all seasons, and is praised as a "movable forest"

Installation and use methods and cases of the control root container

1. Cut the length according to the required diameter, (length: diameter*3.14+10cm overlap)

2. Clip the chassis to the last grid at the bottom of the root controller.

3. Prepare screws (2-3 screws for height 30-40, 3-4 screws for height 50-80)

4. The holey side of the root controller is facing up, and the screws are screwed on the bottom, middle, and top respectively after overlapping.

5. The chassis of the root controller is just stuck on the last protruding grid of the root controller.

6. The installed root control container.

Application value of root controller

1. Convenient transportation

2. Thick and durable PE/PVC/PET

3. Improve survival rate

4. Air trim

5. Drain water and breathe

6. Long-distance transportation