- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Boden Geocell Kies Paddock Extrusion Machine Manufacturers, Suppliers, Factory

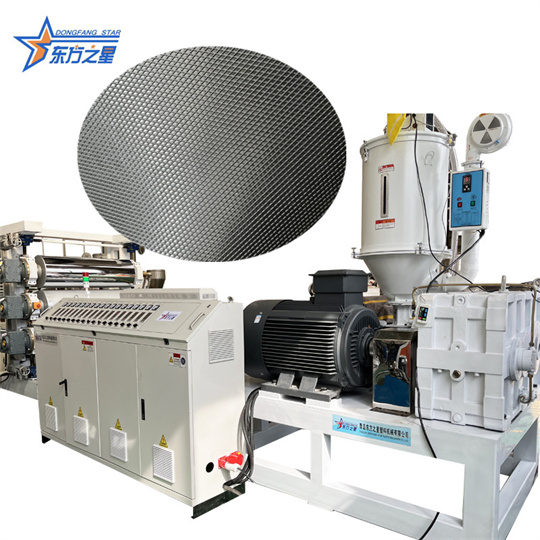

Our company puts emphasis about the administration, the introduction of talented staff, along with the construction of employees building, seeking hard to boost the standard and liability consciousness of staff members members. Our business successfully attained IS9001 Certification and European CE Certification of Boden Geocell Kies Paddock Extrusion Machine,Plastic Gravel Stabilizer Geocell Extrusion Machine,Road Geocel Extrusion Machine,Parking Lot Geocell Extrusion Machine,Slope Stabilization Geocell Extrusion Machine, Sincerely stay up for serving you from the in the vicinity of future. You are sincerely welcome to go to our company to talk company face to face with each other and create long-term co-operation with us!

Boden Geocell Kies Paddock Extrusion Machine, We have been seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

Hot Products

PP Sheet Board Machine

Eaststar, a distinguished manufacturer in the industry, operates a cutting-edge factory dedicated to the production of PP sheet board machines. Renowned for their commitment to excellence, Eaststar designs and manufactures machinery that sets the standard for precision and quality in PP sheet production. With a reputation for innovation and a world-class manufacturing facility, Eaststar stands as a leading force in providing top-tier solutions for the production of PP sheet boards.PE Sheet Extrusion Line

Eaststar stands as a distinguished supplier and manufacturer of PE Sheet Extrusion Lines, renowned for their commitment to customization. With a focus on customization, they ensure that each extrusion line is optimized to meet the unique needs of their clientele, setting a standard of excellence in the field.PS Blister Packaging Sheet Machine

Eaststar, a trusted manufacturer from China, is an expert in producing top-quality PS blister packaging sheet machines. The PS blister packaging sheet machines from Dongfang Star are widely used in various industries and are known for their accuracy, precision, and durability. So, if you're looking for a high-quality PS blister packaging sheet machine, consider Eaststar - you won't be disappointed!Soft Pvc Sheet Extruder Machine

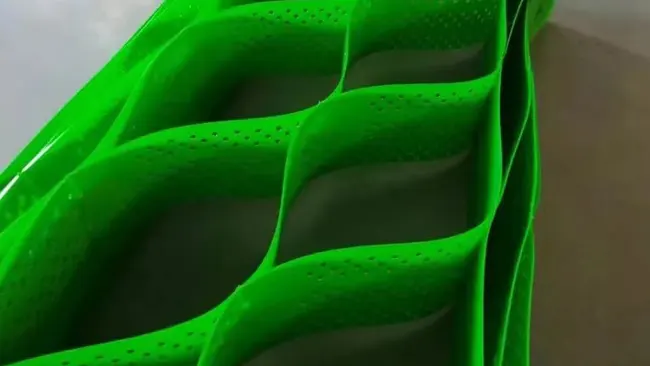

Soft Pvc Sheet Extruder Machine : The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.PVC Sheet Extrusion

As the professional manufacture, EASTSTAR would like to provide you PVC Sheet Extrusion. And EASTSTAR will offer you the best after-sale service and timely delivery.Pvc Lighting Panel Extruder Equipment

pvc lighting panel extruder equipment PVC lighting board extruder equipment: The equipment mainly consists of a twin-screw extruder, a plate mold, a three-roller calender, a cooling bracket, a rubber roller traction machine, a cutting machine, and a conveying device.