- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Geocell production equipment Manufacturers, Suppliers, Factory

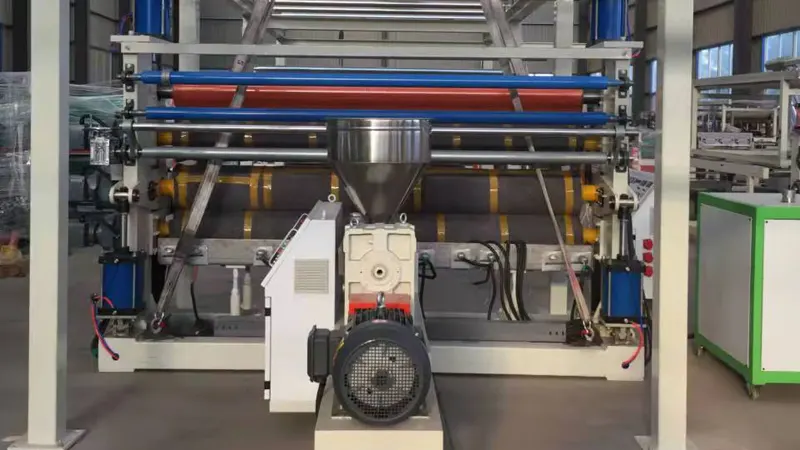

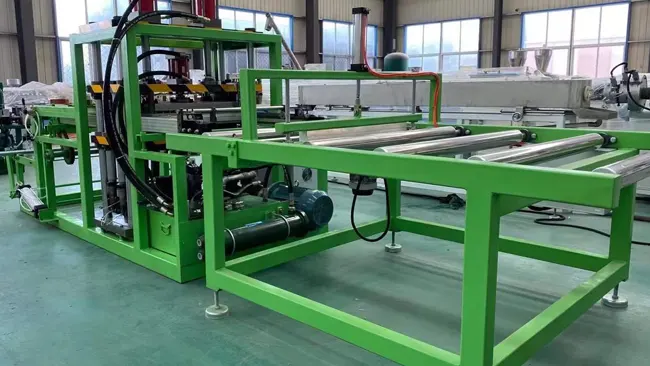

China Geocell production equipment is one kind of products from Eaststar factory. As the one of leading manufacturers and suppliers in China, we provide price list if you want. Our factory offers high quality Geocell production equipment. You can customize our products according to your ideas.We sincerely look forward to becoming your reliable long-term business partner!

Hot Products

PVC Root Controller Machine

Eaststar, a prominent manufacturer based in China, specializes in producing high-quality PVC Root Controller Machines. In addition to their top-notch quality, Eaststar also offers attractive discounts, making their machinery even more accessible to suppliers. By collaborating with reputable suppliers, Eaststar ensures the use of premium-grade components, guaranteeing the efficiency and durability of their machinery.HDPE Sheet Geogrid Equipment

HDPE Sheet Geogrid Equipment is used to produce geocells. The first step of this product is to produce sheets, and then the sheets are cut online, and then the plastic sheets are connected through ultrasonic welding and other methodsPVC Anti-static Board Equipment

PVC Anti-static Board Equipment: The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.PVC Carpet Making Machine

Eaststar, a distinguished manufacturer based in China, stands at the forefront of PVC Carpet Making Machine production. With a strong emphasis on precision engineering, our factory excels in crafting high-quality machinery tailored for efficient PVC carpet manufacturing.Car PVC Flooring Extrusion Machine

Eaststar, a reputable manufacturer in the industry, specializes in producing Car PVC Flooring Extrusion Machines. What sets Eaststar apart is their commitment to providing high-quality machinery at a competitive price point. The Car PVC Flooring Extrusion Machines manufactured by Eaststar are designed to meet the precise requirements of automotive PVC flooring production, ensuring efficiency and precision in every extrusion.Soft Pvc Antistatic Extruder Equipment

Soft Pvc Antistatic Extruder Equipment: The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.