- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Geocell Extrusion Line Manufacturers, Suppliers, Factory

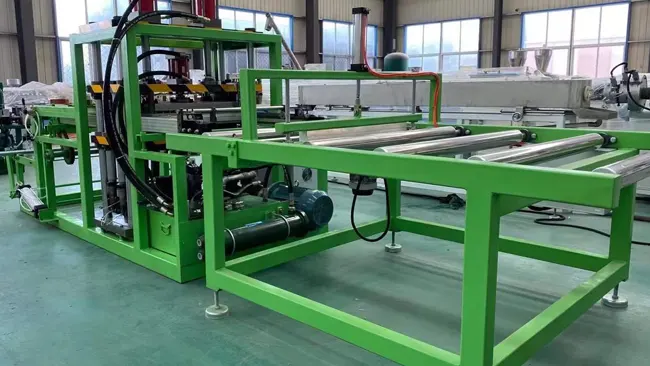

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Geocell Extrusion Line,Hdpe Geocell Sheet Machine,Hdpe Geocell Sheet Machine Extrusion Machine,Hdpe Geomembrane Geocell Sheet Machine,100mm Geocell Extrusion Machine, If possible, make sure you send your necessities with a detailed list including the style/item and quantity you require. We'll then mail our greatest selling prices to you.

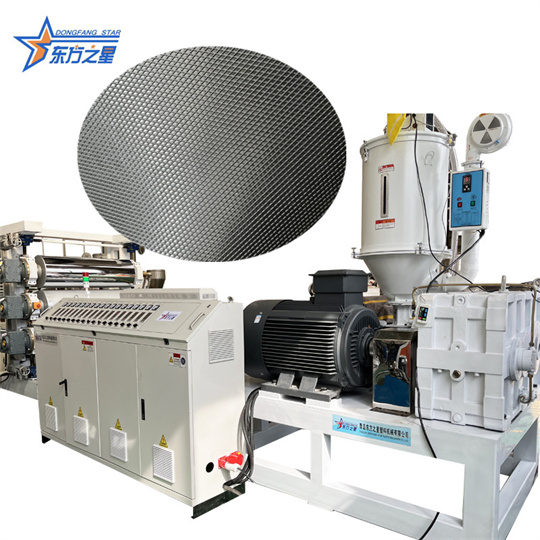

Geocell Extrusion Line, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

Hot Products

PP Sheet Extrusion Line

Eaststar stands out as a prominent supplier and manufacturer in the field of PP Sheet Extrusion Lines. Specializing in customization, they offer top-tier machinery tailored to specific production needs. With Eaststar expertise, you can expect precision and efficiency in the extrusion process, resulting in high-quality PP sheets. Whether for packaging, industrial applications, or any other purpose, their extrusion lines are crafted to deliver outstanding performance.PVC Root Controller Machine

Eaststar, a prominent manufacturer based in China, specializes in producing high-quality PVC Root Controller Machines. In addition to their top-notch quality, Eaststar also offers attractive discounts, making their machinery even more accessible to suppliers. By collaborating with reputable suppliers, Eaststar ensures the use of premium-grade components, guaranteeing the efficiency and durability of their machinery.PET Root Plant Root Protection Equipment

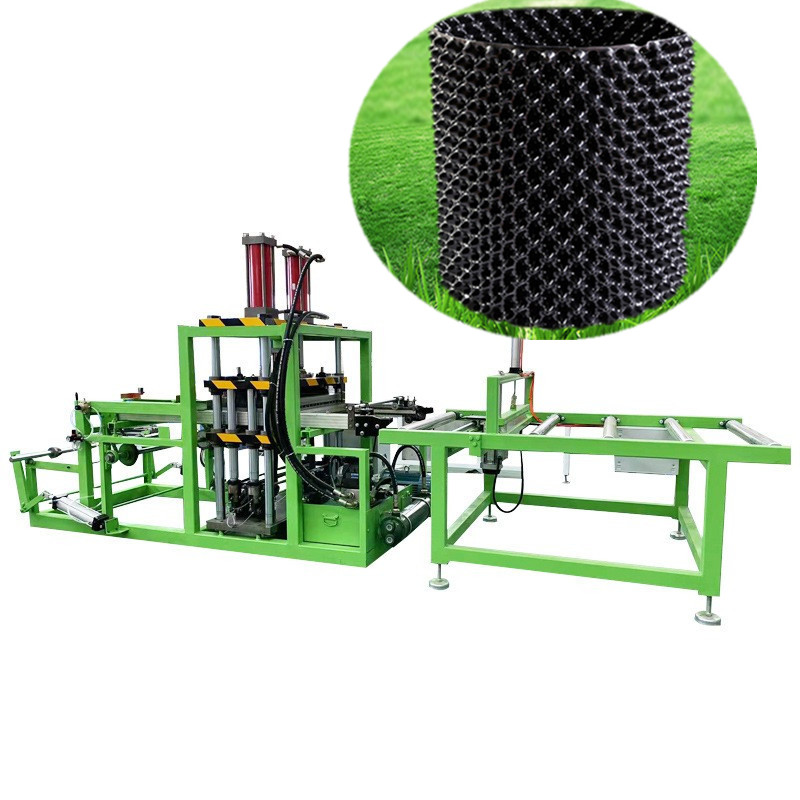

root controldevice is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. PET Root Plant Root Protection Equipment is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reducer motor 0.55KW and 1:10 special reducer, to ensure the stability of feeding speed! 4: Ceramic heating block: new ceramic heating block, heating fast and low power consumption, the temperature can be adjusted freely, according to the thickness of different materials. 5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: Delta PLC control, 6: The machine adopts hydraulic balanced distribution design, the overall balance is better, to solve the situation of the high and low in the production to prolong the use time of the mold.PP PE Coated Pipe system machine

PP PE Coated Pipe system machine PP PE Coated Pipe system machine is mainly used for coating the surface of various metal pipes with a layer of plastic. Stainless steel pipe diameter: 1-200mm can be customized according to customer requirements; Surface coating materials for PP coated pipe equipment: PE, PP, PVC, PA, etc; Coating speed: 0.5-50 meters per minute. Production process of PP coated pipe equipment: Stainless steel pipes on the wire rack or material rack are first preheated by a heating device, then wrapped in plastic by the main machine coating mold, cooled by a circulating water tank, pulled by a traction machine to the wire storage rack, and then automatically cut to a fixed length. Due to different processing techniques for various profiles, the required equipment configuration and equipment are also different.TPE+non-woven Fabric Composite Co-extrusion-waterstop Production Line

TPE+non-woven Fabric Composite Co-extrusion-waterstop Production Line uses co-extrusion to merge a TPE core with a non-woven fabric layer, creating flexible, durable waterstops for concrete joints. The process ensures high-quality, consistent output, ideal for construction applications requiring reliable waterproofing.PC PS ABS lamp cover production line

Qingdao Eaststar, a professional manufacturer of PC PS ABS lamp cover production lines, proudly presents this high-performance PC/PS/ABS lamp cover production line. This line integrates high plasticization rate, fully automated control, and stable continuous production, specifically designed for producing high-precision, high-quality LED lamp diffusers. It utilizes high-quality 38CrMoAlA nitriding screws and barrels, along with imported brand electrical components, ensuring the equipment's durability. Contact us now for a customized quote and technical support!