- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Geocel Hdpe Extrusion Machine Manufacturers, Suppliers, Factory

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Geocel Hdpe Extrusion Machine,Honeycomb Geocell Extrusion Machine,Geocell Geoweb Extrusion Machine,Geocell Envirogrid Extrusion Machine,Geocell 2300 Extrusion Machine, we could solve our customer problems asap and do the profit for our customer. For those who need excellent company and top quality , pls choose us , thanks !

Geocel Hdpe Extrusion Machine, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Hot Products

PLA Degradable Plastic Sheet Extrusion Machine

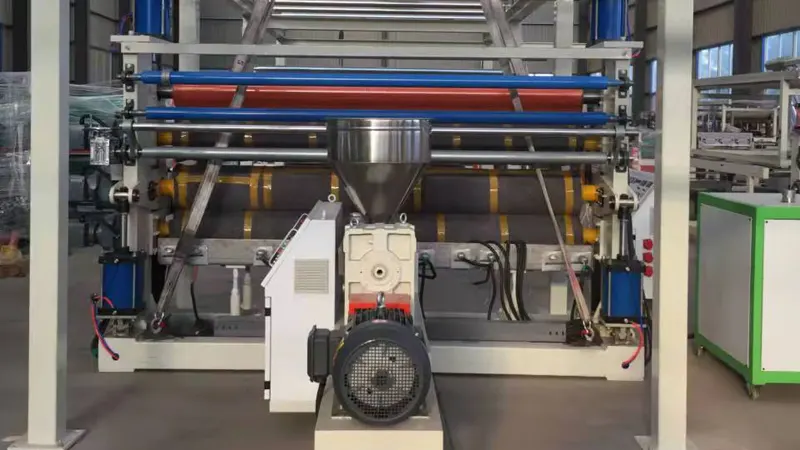

If you're in search of a PLA Degradable Plastic Sheet Extrusion Machine, our esteemed factory has you covered. What's more, for a limited time, we're offering exclusive discounts on this state-of-the-art machinery.Don't miss out on this opportunity to enhance your production capabilities while enjoying significant cost savings.HDPE Geogrid extruder production line

HDPE Geogrid extruder production line is used to produce geocells. The first step of this product is to produce sheets, and then the sheets are cut online, and then the plastic sheets are connected through ultrasonic welding and other methodsDisposable Seedling Cup Plug Equipment

Disposable Seedling Cup Plug Equipment technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm. Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mmGeocell Production Line

Experience the pinnacle of quality with our Geocell Production Line, proudly manufactured in China. Geocells, known for their exceptional strength and durability, find diverse applications in infrastructure and environmental projects. With our high-quality production line, you can trust that your geocells will meet the rigorous demands of any project. Elevate your construction endeavors with the reliability and excellence of our Geocell Production Line.PE Luggage Edge Srip Equipment

PE Luggage Edge Srip Equipment includes single screw compressor - machine head mold - vacuum shaping warehouse - traction tractor - winding machine or cutting machine 1. The main machine adopts hard tooth surface stop machine transmission, the screw barrel is made of high-strength quenched alloy steel (38CrMoALA) or high-strength quenched alloy steel (9Cr18MoV), and the main machine drive adopts AC variable frequency controller, no oil stains, low noise; temperature control The device adopts an intelligent temperature control meter, and the temperature control accuracy reaches ±1℃; 2. The main body of the stainless steel cooling pool is made of imported SUS304 material; the water tank frame adopts a threaded lift device, which can be adjusted in three dimensions up, down, left and right, making the operation very convenient; it is also equipped with a stainless steel water storage tank, so that the cooling water can be recycled without splashing on the ground; 3. The traction machine has variable frequency controller and the traction speed is steplessly adjustable. 4. The winding machine adopts frequency converter to adjust the speed to achieve the ideal production speed.PVC Antistatic Sheet Extruder Equipment

PVC Antistatic Sheet Extruder Equipment: The equipment mainly consists of a 120 single screw extruder, a three-roller calender, a cooling bracket, a rubber roller traction machine, a shearing machine, and a conveyor belt device. The standard width of the PVC turtle back panel equipment product is 1000mm. The thickness is 6mm. PVC antistatic extruder board equipment can produce various textures such as turtle pattern, orange peel pattern, and checkered pattern. PVC turtle board equipment can be processed and customized according to customer requirements.