- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Products

- View as

PP Coated Pipe Equipment

PP coated pipe equipment PP coated pipe equipment is mainly used for coating the surface of various metal pipes with a layer of plastic. Stainless steel pipe diameter: 1-200mm can be customized according to customer requirements; Surface coating materials for PP coated pipe equipment: PE, PP, PVC, PA, etc; Coating speed: 0.5-50 meters per minute. Production process of PP coated pipe equipment: Stainless steel pipes on the wire rack or material rack are first preheated by a heating device, then wrapped in plastic by the main machine coating mold, cooled by a circulating water tank, pulled by a traction machine to the wire storage rack, and then automatically cut to a fixed length. Due to different processing techniques for various profiles, the required equip......

Read MoreSend InquiryPVC Transparent Soft Door Curtains Machine

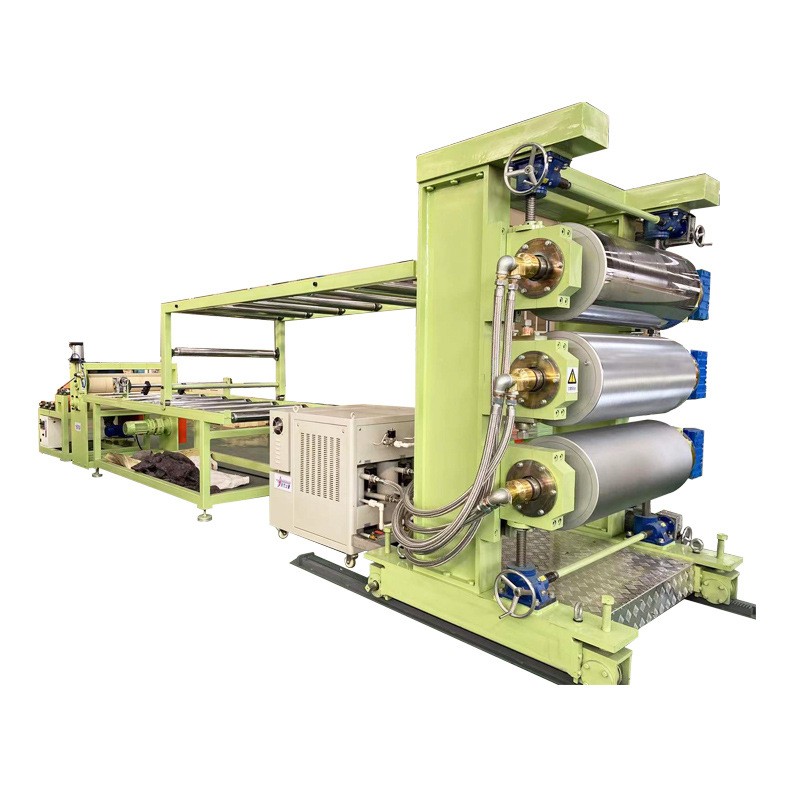

PVC Transparent Soft Door Curtains Machine Qingdao EAST STAR Plastic Machinery Co., Ltd. is mainly engaged in plastic sheet equipment. Our company's PVC soft door curtain equipment mainly consists of five parts: super mirror roller part, motor drive system, gap adjustment system, electrical control system, and frame. composition. Our company's PVC soft door curtain equipment can produce PVC transparent soft door curtains with a width of 200-400 mm and a thickness of 0.5-5 mm. This PVC soft door curtain equipment can produce three types of soft door curtains, including glossy, matte and striped, in one machine. It not only achieves multiple uses in one machine and is easy to operate, but also helps customers greatly save costs.

Read MoreSend InquiryPVC Soft Door Curtain Equipment Soft PVC Striped Door Curtain Equipment

PVC Soft Door Curtain Equipment Soft PVC Striped Door Curtain Equipment Characteristics of PVC soft door curtain equipment three-roller calender PVC Soft Door Curtain Equipment calender: It is mainly composed of 5 parts including super mirror roller part, motor drive system, gap adjustment system, electrical control system, and fan. A set of PVC soft door curtain three-roller calendering machine can produce PVC transparent soft door curtains with a width of 200-400 mm and a thickness of 0.5-5 mm. This three-roller calendering machine for PVC soft door curtains can produce glossy, matte, and striped colored soft door curtains in one machine. It is easy to operate.

Read MoreSend InquiryPET Root Plant Root Protection Equipment

root controldevice is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. PET Root Plant Root Protection Equipment is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reduce......

Read MoreSend InquiryRoot Control Making Machine PS Root Controller Forming Machine

Root Control Making Machine PS Root Controller Forming Machine root controldevice is mainly in accordance with the working principle of hot pressing equipment design. Root control equipment can also produce water spraying sheets 1. Root Control Making Machine is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a ......

Read MoreSend InquiryProfile Production Line

Profile Production Line The profile production line uses SJSZ-65/132 series conical twin-screw extruders, stainless steel vacuum shaping platforms, crawler tractors, automatic cutting integrated machines, and flipping unloading racks. The shaping platform is equipped with a high-pressure vacuum pump and a water pump, which are four-dimensionally adjustable. The tractor is pneumatically clamped. The automatic fixed-length cutting machine uses a travel switch to cut to a fixed length. The stacking rack is 6 meters long, made of stainless steel, and pneumatically flipped.

Read MoreSend Inquiry