- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

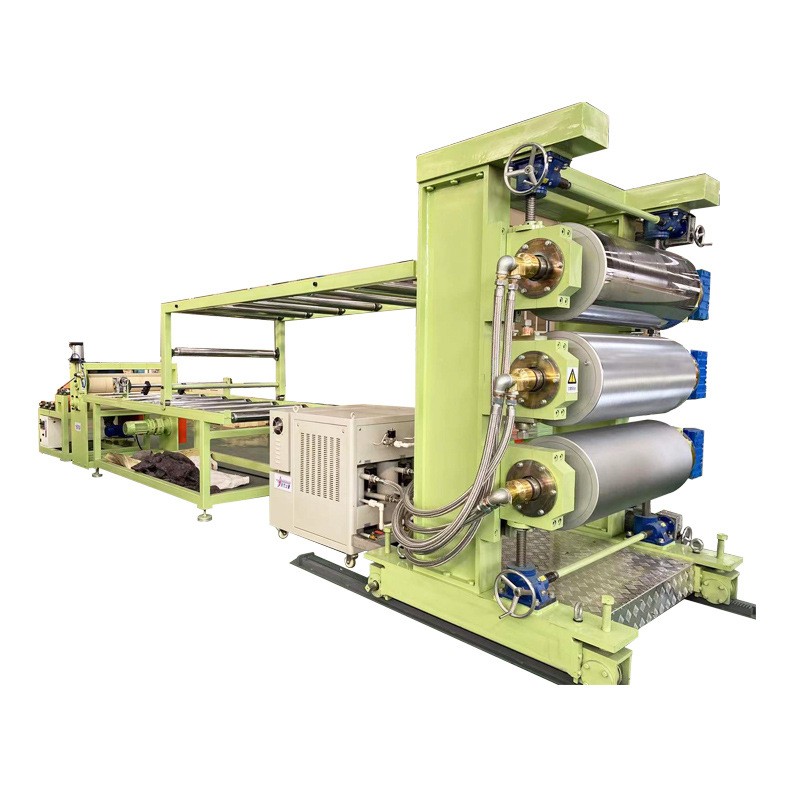

PVC Transparent Crystal Board Production Line

PVC Transparent Crystal Board Production Line Eaststar, a reputable manufacturer based in China, specializes in producing state-of-the-art PVC PVC transparent door curtain production line. These cutting-edge machines are meticulously designed to facilitate the extrusion process of PVC materials, particularly for exterior curtain applications.

Send Inquiry

With a focus on quality and innovation, PVC transparent crystal board production line are crafted to meet industry standards, ensuring reliability and efficiency in production. Trust in Eaststar for top-notch machinery that's proudly made in China.

Introducing an advanced production line designed for the manufacture of PVC transparent crystal board production line. This state-of-the-art line is tailored to produce PVC transparent plastic sheets with a width range spanning from 200 to 600 millimeters, and a thickness varying from 0.8 to 3 millimeters. Equipped with cutting-edge machinery including a single-screw extruder (SJ90 or SJ-120), a versatile T-shaped flexible die, and a three-roller calender, either vertically oriented or inclined at a 45-degree angle. Additionally, it incorporates a water temperature controller, a stainless steel cooling bracket with an adjustable trimming knife, a rubber roller traction machine, and a dual-position air-expanding shaft winder.

The resulting sheets boast an impressive array of characteristics. They feature a lustrous surface ensuring exceptional transparency and a pliable, crack-resistant composition. What's more, they are distinguished by their lack of scent and absence of bubbles. Significantly, these sheets offer flexibility coupled with resilience to low temperatures, abrasion, exposure to acid-alkali substances, and corrosion.

PVC Transparent Crystal Board Production Line