- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

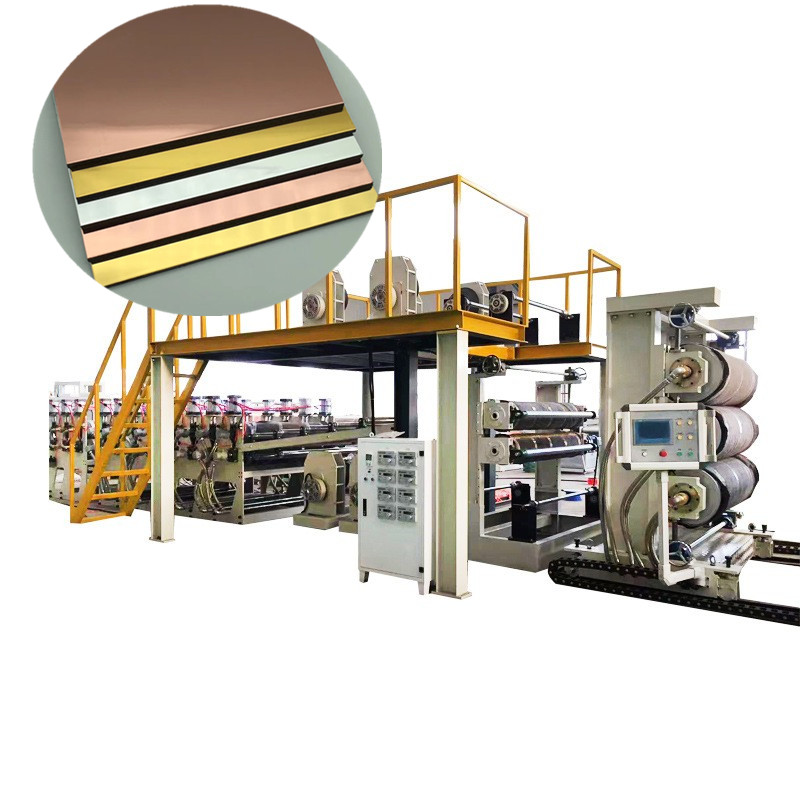

China Hdpe Geocell Sheet Machine Extrusion Machine Manufacturers, Suppliers, Factory

We've got a highly efficient group to deal with inquiries from shoppers. Our purpose is "100% client fulfillment by our product high-quality, price tag & our staff service" and enjoy a superb reputation amongst clientele. With quite a few factories, we will provide a wide variety of Hdpe Geocell Sheet Machine Extrusion Machine,Hdpe Geocell Sheet Machine,Hdpe Geomembrane Geocell Sheet Machine,Geocell Extrusion Line,100mm Geocell Extrusion Machine, Initial enterprise, we understand each other. Additional enterprise, the trust is getting there. Our firm usually at your service anytime.

Hdpe Geocell Sheet Machine Extrusion Machine, To create more creative goods, maintain high-quality goods and update not only our merchandise but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we provide and to grow stronger together. To be the real winner, starts here!

Hot Products

PC Plastic Sheet Extrusion Machine

Eaststar is a leading manufacturer and factory of PC plastic sheet extrusion machines. Our state-of-the-art machinery is designed with precision and efficiency in mind and has been trusted by our clients for years. As a dedicated manufacturer, we strive to provide our customers with the highest quality products and services. With our expertise and knowledge, we ensure that our PC plastic sheet extrusion machines meet the demanding needs of our clients. Choose Eaststar for all your plastic sheet extrusion needs and experience the difference that comes with working with a top-tier manufacturer.Car Floor Mats Overlock Sewing Machine

Eaststar, a renowned factory, specializes in producing Car Floor Mats Overlock Sewing Machines. What sets Eaststar apart is their commitment to providing high-quality machinery at a competitive price point. Our dedication to affordability and quality makes them a trusted choice for manufacturers in the automotive industry.Seedling Pot Tray Making Machine

Collaborating with reputable suppliers, Eaststar ensures the use of top-notch components, guaranteeing the efficiency and durability of their machinery. Suppliers worldwide turn to Eaststar for their advanced technology and reliable production capabilities in Seedling Pot Tray Making Machines.PS PET Seeding Tray Making Machine

PS PET seeding tray making machine technical parameter Specification width of used sheet: 300~320mm, thickness: 0.8~2mm.PS PET Seeding Tray Making Machine Forming area (maximum): 400*600 mm, working efficiency of 15~20 times / minute. Power used: three-phase four-wire 380 volts, maximum power 25KW Hydraulic pressure: 100T External size (mm) length, width and height) 3600mm*980mm*1500mmPvc Canopy Panel Equipment

The PVC canopy panel equipment mainly consists of a twin-screw extruder, a plate mold, a three-roller calender, a cooling bracket, a rubber roller traction machine, a cutting machine, and a conveying device.High Quality Aluminum Plastic Panel Recycling Equipment

Qingdao East Star Plastic Machinery Co., Ltd. is mainly engaged in sheet material extruder equipment. High Quality Aluminum Plastic Panel Recycling Equipment is one of the important products produced by our company. We can match the equipment with corresponding output according to customer requirements. Friends from all over the world are welcome to purchase equipment.