- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

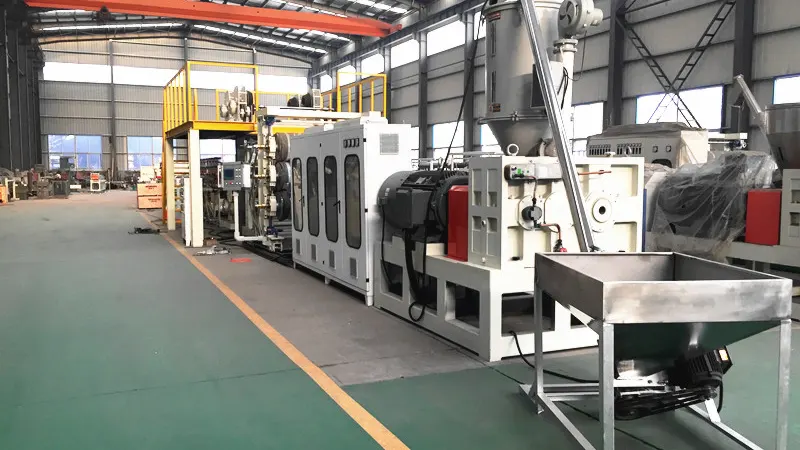

China Hdpe Geocell Plastic Gravel Grid Extrusion Machine Manufacturers, Suppliers, Factory

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Hdpe Geocell Plastic Gravel Grid Extrusion Machine,Geocells Making Machine,Smooth Geocell Machine,Stabilizer Geocell Making Machine,Plastic Geocells Making Machine, Besides, our firm sticks to high quality and affordable cost, and we also present great OEM companies to many famous brands.

Hdpe Geocell Plastic Gravel Grid Extrusion Machine, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Hot Products

PLA Degradable Plastic Sheet Extrusion Machine

If you're in search of a PLA Degradable Plastic Sheet Extrusion Machine, our esteemed factory has you covered. What's more, for a limited time, we're offering exclusive discounts on this state-of-the-art machinery.Don't miss out on this opportunity to enhance your production capabilities while enjoying significant cost savings.Planting Trays Seedling Making Machine

Eaststar, a distinguished manufacturer based in China, specializes in the production of high-quality Planting Trays Seedling Making Machines. Collaborating with reputable suppliers, Eaststar sources top-notch components, guaranteeing the exceptional performance and reliability of their machinery. Eaststar's Planting Trays Seedling Making Machines are trusted by suppliers worldwide for their advanced technology and reliable production capabilities.PE Aluminum-Plastic Composite Panel Production Line

PE Aluminum-Plastic Composite Panel Production Line (also known as aluminum-plastic panel), as a new building material, and has been quickly favored by people for its economy, the diversity of optional colors, convenient construction methods, excellent processing performance, excellent fire resistance and noble quality. The unique properties of aluminum-plastic composite board determine its wide range of uses: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, purification and dust prevention projects. It belongs to a new type of building material. The products produced by the equipment are mainly suitable for the inner and outer wall PE composite board, the thickness of the product is from 1-6mm, the width of 1200-1500mm two models, the thickness of the aluminum foil is from 0.03-0.5mm, and the bonding process of polymer film or glue can be selected. The equipment has the advantages of one molding, stable extrusion, firm compound, good flatness and so on.PE PP Control Root Board Making Machine

PE PP Control Root Board Making Machine with the working principle of hot pressing equipment design. PE PP Control Root Board Making Machine can also produce water spraying sheets 1. PET Root Plant Root Protection Equipment is mainly in accordance with the working principle of hot pressing equipment design, process is: sheet —— feeding —— heating —— pressing —— pressure —— molding —— cutting steps, appearance neat and practical, plate processing all processing center, ensure the accuracy of all hole size, column and pin appearance are hard chromium quenching treatment, ensure the sliding and wear resistance, machine system edited into manual and automatic two parts, in manual case all action can be single operation. 2: The feed motor is driven by a servo motor with a power of 2 kW. 3: feeding reducer motor 0.55KW and 1:10 special reducer, to ensure the stability of feeding speed! 4: Ceramic heating block: new ceramic heating block, heating fast and low power consumption, the temperature can be adjusted freely, according to the thickness of different materials. 5: Other mechanical parts are produced and processed by our company. Automatic control system adopts: Delta PLC control, 6: The machine adopts hydraulic balanced distribution design, the overall balance is better, to solve the situation of the high and low in the production to prolong the use time of the mold.Sheet Three-roller Calender Equipment

Sheet three-roller calender equipment: It is mainly composed of five parts: super mirror roller part, motor drive system, gap adjustment system, electrical control system, and frame. Rollers with different widths and thicknesses can be ordered and produced according to customer requirements. The surface of the roller can be smooth, matte, orange peel, diamond, or tortoise. The three-roller calender can be used for a variety of plastic sheets. Calender cooling molding: used for extrusion of PE, PP, PVC, ABS, PC, POM and other materials.PVC chicken trough production line

This PVC chicken trough production line uses a fully automatic extrusion molding process to professionally manufacture corrosion-resistant, lightweight and durable PVC chicken feeders, effectively meeting the efficient feeding needs of modern large-scale farms.